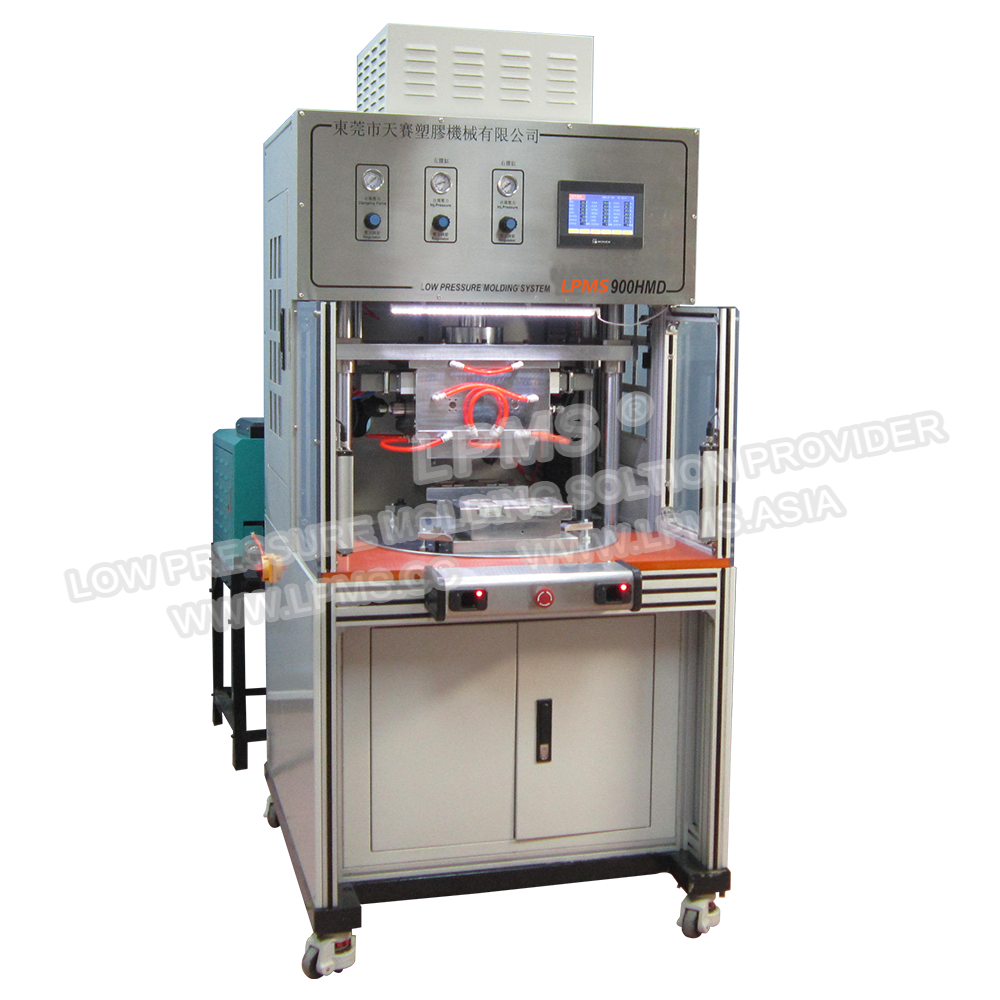

l Intuitive touch screen operation, which is on the rotary operator.

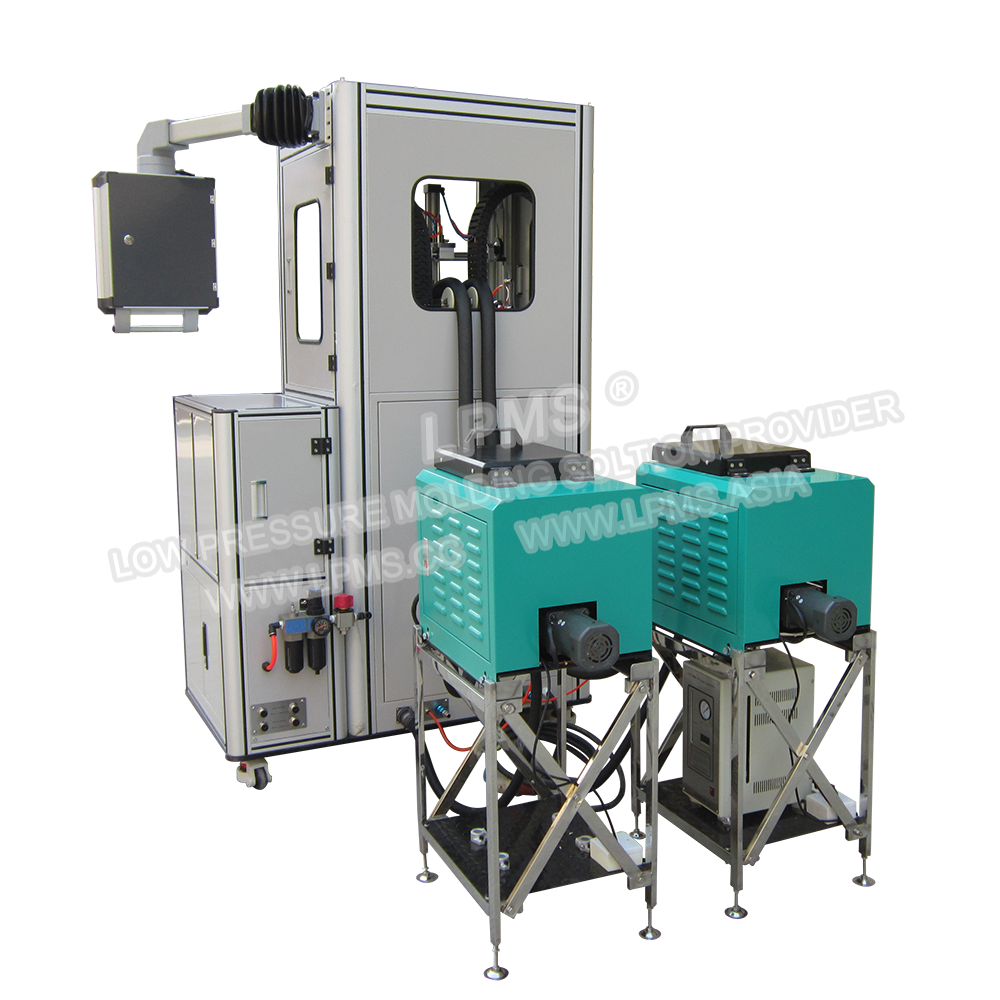

l Air over oil cylinder gives large clamping force for larger part.

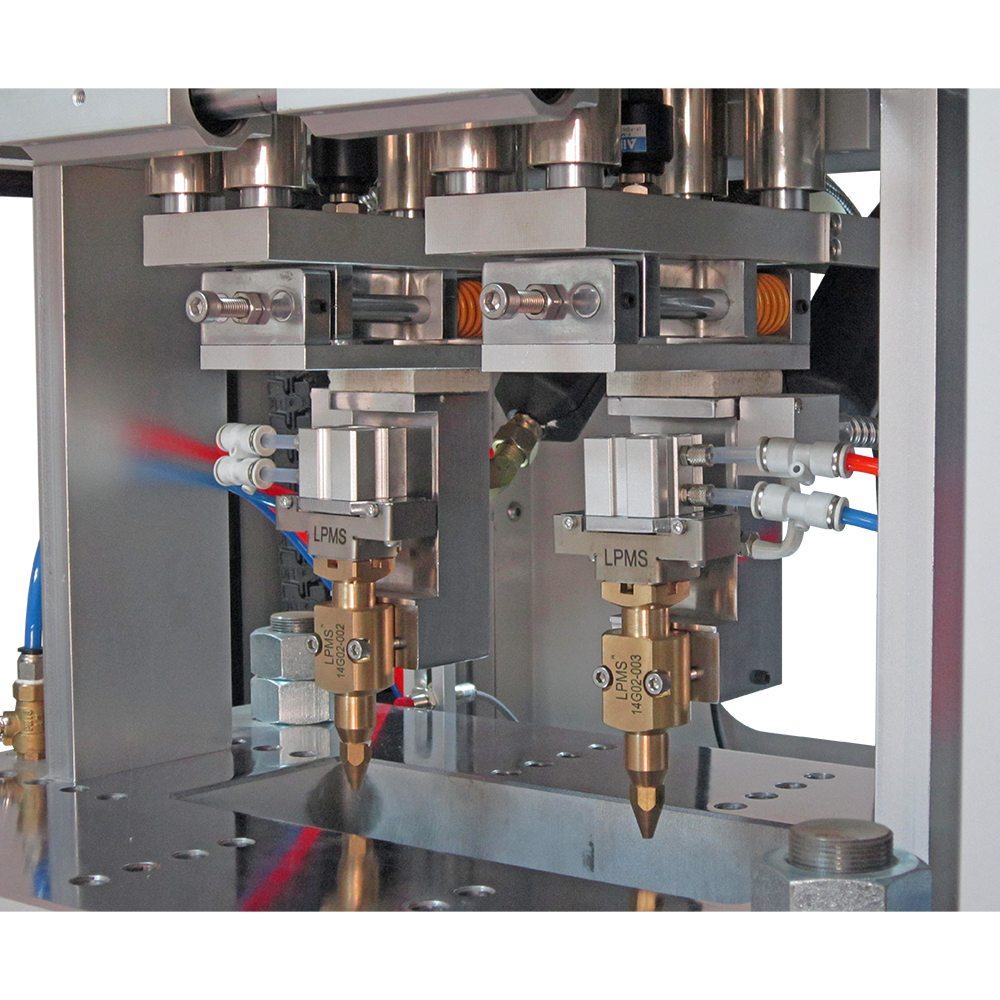

l Two independent injection guns.

l Dual 7 liter melting tanks. Run different molding materials at the same time.

l LPMS specially designed melt-on-demand tank can melt down the resin swiftly and evenly.

l The gear pump is made of hard-wearing material,which is stable,injection volume accuracy ±0.1g,maximum shot size is 5g/s.

l Injection pressure range 1~50kg, which is controlled by pneumatic safety valve. LPMS also have option like electronic safety valve, which means the injection pressure can be set more precisely from the PLC.

l Linear scale it’s precise for mold clamping, does not need to adjust the reed switch position.

l Six thermal control zones for precise melt control.

l Light curtain and dual palm buttons for operator safety.

Application

LPMS? machines are engineered for low pressure molding, using specialty resins to encapsulate delicate parts, like automotive electronics, PCBA, coil, fiber-optic, LED lighting, cable, etc.

The benefit of vertical injection is that when smaller parts allow the cavity to be split into two or four cavities. This allows shorter runners and higher output per cycle. It’s suitable for multiple cavity mold for cable, wire harness, LED, etc.

Specification

Machine Size / Weight | 1245 mm x 945 mm x 1980 mm / 660 kg 49.01 in x 37.20 in x 77.95 in / 1454 lbs |

Footprint | 1245 mm x 1700 mm | 49.01 in x 66.93 in |

Working Station Height | 1120 mm | 44.09 in |

Packing Size / Weight | 1330 mm x 960 mm x 2130 mm / 700 kg 52.36 in x 37.80 in x 83.86 in / 1543 lbs |

Melting Tank | Melt on demand 7 liter x 2 |

Auto Feeding System | Optional |

Gun Model & Tip | LPMS-G08 x 2 / 36.4° |

Gun distance | 100mm-200mm | 3.94 in – 7.88 in |

Ejectors distance | 50 mm | 1.97 in |

Heated Hose | 1.6 m x 2 |

Electricity | 200-240VAC / 1 Phase / 50Hz |

Temperature Control Zones | 6 |

Temperature Range | Ambient up to 250°C / 485°F |

Max .Power | 10 Kw |

Min. Air Pressure | 0.5MPa | 73 Psi |

Air Consumption | 0.1 m3/min | 3.5 ft3/min |

Clamping | Air over oil cylinder |

Clamping Force | Max. 5 Tons ( Optional 10 Tons ) |

Clamping Stroke | 150 mm | 5.91 in |

Control System | 7 ”HMI , PLC controlled |

Safety Protection | See-thru clamp shield, emergency stop button |

Max. Mold Set Size | 400 mm x 300 mm x 150 mm 15.75 in x 11.81 in x 5.90 in |

Min. Mold Set Size | 200 mm x 150 mm x150 mm 7.87 in x 5.90 in x 5.90 in |

Dimension

Machine dimension

Mold set dimension

Video

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.